Product Description

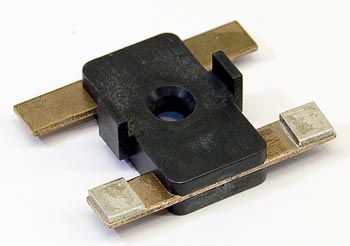

Contact - Moveable

Frequently Asked Questions

Q: What is the CR 078912-002 moveable contact and what does it do?

A: The CR 078912-002 is a moveable electrical contact in the motor control relay or contactor of Crown electric lift trucks. This contact moves to make or break electrical circuits that control motor operation. When the control switch is activated, the moveable contact connects power to the motor.

Q: Which Crown truck models require the CR 078912-002 moveable contact?

A: The CR 078912-002 is a Crown OEM component for specific motor control assemblies on electric lift trucks. Your exact truck model, motor specification, and control system design determine whether this part is needed. Provide your Crown truck serial number or model designation for verification.

Q: What are the specifications for the CR 078912-002 moveable contact?

A: The CR 078912-002 is engineered for specific voltage, amperage capacity, and switching speed to match your Crown motor control system. Exact electrical ratings and mounting specifications are found in your truck motor control documentation. Operating the contact beyond its rated capacity causes permanent damage.

Q: When should the CR 078912-002 moveable contact be replaced?

A: Replace this contact if the motor exhibits intermittent response, fails to start, or if electrical testing shows excessive resistance or pitting on the contact surface. Signs include burning smell from the control module, arcing when activating controls, or loss of electrical continuity.

Q: How does the CR 078912-002 moveable contact differ from the CR 078912-001?

A: The CR 078912-001 is a stationary fixed contact while the CR 078912-002 is the moving component that bridges electrical connections. Both contacts work as a pair in the motor control relay or contactor. They must be replaced together if either contact becomes worn or damaged.

Q: What causes the CR 078912-002 moveable contact to wear out?

A: Wear occurs from repeated electrical arcing during switching, oxidation from moisture and heat, and mechanical friction. Overloading the truck motor causes excessive arcing and faster contact erosion. High-amperage transients and poor electrical connections increase contact wear. Regular control system inspection helps identify worn contacts before failure.