Product Description

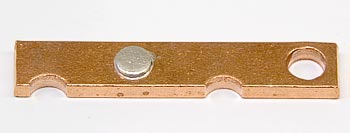

Caterpillar CT 215571 Tip for electric lift trucks is an OEM part designed for EC25N and EC30N models. Manufactured from high-strength alloy steel, its dimensions suit Caterpillar fork carriages for heavy-duty load handling. Includes rated capacity and installation specs. Cross-reference part numbers not available.

Specifications

Material & Construction

| Finish | Powder coated industrial finish |

Part Numbers

| OEM Part Number | CT 215571 |

| Manufacturer Part Number | CT 215571 |