Product Description

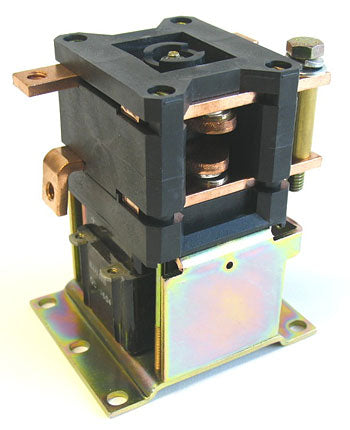

CONTACTOR 24V, FORWARD

Frequently Asked Questions

Q: What voltage and amperage does the GE A702BE305X0-1 contactor handle?

A: The GE A702BE305X0-1 is a 24-volt forward contactor rated for electric lift truck systems. Verify the amperage rating from your equipment schematic or contactor data plate to ensure this part meets your circuit requirements. This contactor directs current flow to the forward motor function.

Q: Which lift truck brands use the GE A702BE305X0-1 contactor?

A: The GE A702BE305X0-1 is compatible with 24-volt electric lift trucks from Crown, Toyota, Raymond, Yale, Hyster, and similar manufacturers. Fitment depends on contactor mounting configuration and electrical schematic design. Verify compatibility with your specific equipment model before ordering.

Q: How do I know if the GE A702BE305X0-1 contactor has failed?

A: Signs of contactor failure include no response when engaging forward motion, audible chattering from the contactor, burning smell near the electrical enclosure, or visible pitting on internal contacts. If forward function does not engage but reverse works, the forward contactor likely needs replacement.

Q: What is the lifespan of the GE A702BE305X0-1 contactor?

A: Under normal operation, the GE A702BE305X0-1 typically lasts 3 to 7 years. Lifespan depends on cycle frequency, load conditions, and electrical maintenance. Frequent duty cycles or contaminated enclosures reduce lifespan. Replace when contacts weld or fail to engage forward motion reliably.

Q: Can the GE A702BE305X0-1 be used in reverse-only applications?

A: No. The GE A702BE305X0-1 is designed specifically for forward motor control. Using it for reverse operation or as a general-purpose contactor may cause overheating and failure. Use the correct forward or reverse contactor for each function as specified in your equipment wiring diagram.

Q: How should the GE A702BE305X0-1 contactor be stored and maintained?

A: Store the contactor in a dry location protected from dust and moisture. Keep the electrical enclosure clean and ensure proper ventilation to prevent heat buildup. Periodically inspect for corrosion, loose terminals, or contact pitting. Replace gaskets or seals if water ingress is suspected.