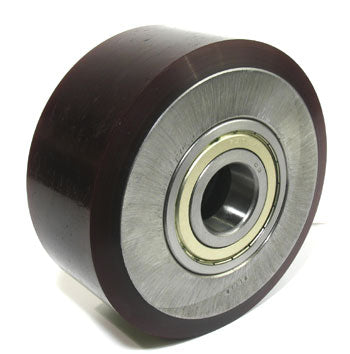

Product Description

Load Wheel Assembly

Specifications: 6.000 inch diameter x 2.750 inch width (6.000" x 2.750" | 6 x 2.75 wheel | 6 x 2-3/4 | 152.40mm x 69.85mm)

Specifications

Wheel Dimensions

| Material | |

| Outside Diameter | 6 |

| Inside Diameter | 2.75 |

| Width Side to Side | 2.75 |

| Tread Profile | 3/8 Radius |

| Bore Depth | 0.83 |

| Hub Width | |

| Bore Outside Diameter | 3.1491 |

Frequently Asked Questions

Q: What is the difference between SU S9111-A and SU S9111-EZ-A load wheel assemblies?

A: SU S9111-A is a standard load wheel assembly with 6-inch OD x 2.75-inch width. SU S9111-EZ-A is the EZ variant, offering simplified installation. Both share identical dimensions (152.40mm x 69.85mm). Choose SU S9111-A for standard Superior equipment; select SU S9111-EZ-A if your truck model requires quick-change wheel design. Cross-reference with your pallet jack serial number to verify which assembly your model accepts.

Q: Can I install SU S9111-A wheels on a three-wheeled electric pallet jack with worn load wheels?

A: Yes, if the truck model is rated for 6-inch diameter wheels. Before installation, inspect the bearing hubs for pitting or corrosion. If hubs are damaged, replace them before mounting new wheels. Verify that the bore depth (0.83 inches) and bore OD (3.1491 inches) match your trucks hub specifications. Torque the axle bolt to manufacturer spec (typically 35-45 ft-lbs for Superior models) to prevent wheel wobble during operation.

Q: What load capacity does the SU S9111-A assembly support?

A: Load capacity depends on the complete truck assembly and number of load wheels. SU S9111-A wheels themselves are engineered for high-cycle warehouse duty. For a 6000-lb pallet truck, each load wheel typically carries 1500-2000 lbs. Do not exceed the truck nameplate rated capacity. If wheels show flat spots, cracking, or excessive wear after 500 operating hours, this indicates overloading or improper maintenance.

Q: How do I diagnose if SU S9111-A wheels are failing?

A: Check for these symptoms: (1) Visible cracks, chunks missing, or flat spots on the tread; (2) Wobbling or lateral play when manually spinning the wheel; (3) Audible grinding or clicking during operation; (4) Uneven wear pattern indicating misalignment. Spin each wheel by hand and listen for bearing noise. If worn, replace the complete assembly. Do not attempt to retrench or repair damaged polyurethane treads in the field.

Q: What bearing type pairs with SU S9111-A assemblies?

A: SU S9111-A uses standard 6203-2RS ball bearings (20mm bore, 47mm OD, 14mm width) mounted inside the wheel hub. If bearings require replacement, press them with the sealed side facing outward. Verify bearing preload by spinning the wheel—it should rotate freely with minimal drag. Grease-sealed bearings do not require periodic lubrication. If bearings fail prematurely, check for contamination from water or salt spray and ensure wheels are stored in a dry environment.

Q: What is the expected service life of SU S9111-A wheels?

A: Under normal warehouse conditions (8-hour shift, concrete floors, within rated load), expect 1-2 years or 2000-3000 operating hours before tread wear requires replacement. Lifespan varies based on floor surface (concrete extends life; rough unfinished concrete reduces it), weight carried, and storage conditions. If stored indoors without humidity control, polyurethane can harden and crack. Replace proactively when tread depth reduces to 1/8 inch or sooner if floor damage or instability occurs.