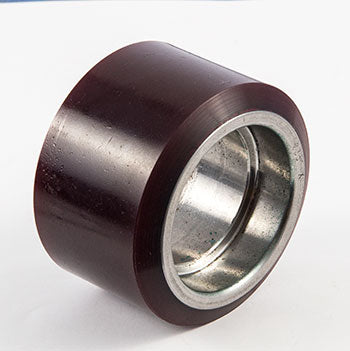

Product Description

Load Wheel

Frequently Asked Questions

Q: Is the SU 2350 load wheel compatible with Crown, Toyota, and Raymond electric lift trucks?

A: The SU 2350 is an aftermarket replacement wheel. Compatibility depends on your truck model, load wheel pocket design, and axle diameter. Verify your OEM part number first, then cross-reference with Superior documentation. Do not force-fit wheels with incorrect bore diameters as this will cause premature bearing wear and load shift.

Q: What should I check if the SU 2350 load wheel develops wobble or vibration after installation?

A: First, verify the wheel is fully seated on the axle and the retaining nut is torqued to spec (typically 40-60 ft-lbs depending on axle size). Check for wheel runout using a dial indicator mounted at the tire edge; acceptable runout is under 0.100 inch. Inspect the wheel bore for damage or wear. If runout exceeds limits, the wheel hub may be bent or the bearing race may be damaged and require replacement.

Q: Can I use the SU 2350 load wheel in wet or corrosive warehouse environments?

A: The SU 2350 is an industrial-grade load wheel designed for standard warehouse use. Prolonged exposure to water, salt, or caustic chemicals will accelerate corrosion on the metal hub and reduce bearing life. Store wheels in a dry area and wash with fresh water if exposed to salt spray. For chemical environments, confirm material specifications with Superior before deployment.

Q: What is the maximum load rating for the SU 2350 load wheel?

A: Load capacity depends on wheel diameter, width, material, bearing type, and axle configuration. Superior provides load ratings on the product datasheet; typical load wheels carry 1500 to 3000 lbs per wheel depending on design. Do not exceed the rated load per wheel. Overloading causes bearing premature failure, wheel deformation, and potential load drop.

Q: How often should I replace the SU 2350 load wheel?

A: Replace when the tire is worn below 50 percent depth, when bearing noise or play is detected, when the wheel develops flat spots or cracks, or when hub damage is visible. In high-use environments, expect 2 to 5 years of service life. Perform bearing lubrication every 12 months on grease-packed wheels. If the bearing is sealed and the wheel does not roll smoothly, replacement is required.

Q: Do I need tools to install the SU 2350 load wheel?

A: Yes. You will need a socket wrench or spanner to remove the axle nut, a bearing puller or press to remove the old wheel, and a press to install the new wheel onto the axle. Do not hammer or drive the wheel onto the axle as this will damage the bearing race and bore. Torque the axle nut to OEM specification after installation.