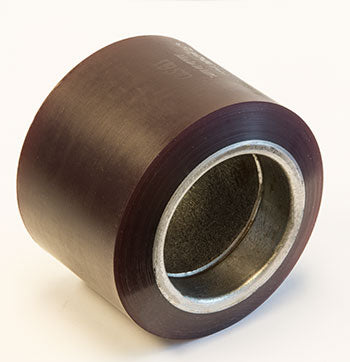

Product Description

Load Wheel

Frequently Asked Questions

Q: What is the load capacity of SU S339 load wheels?

A: SU S339 is rated for 1800 lbs per wheel and is designed for lighter-duty electric pallet jacks and low-capacity hand trucks. Do not use SU S339 on 3000 lbs or higher capacity trucks as the wheel will deform under load.

Q: Can I use SU S339 as a direct replacement for SU S338?

A: No. SU S339 has a smaller hub diameter (1.25 inch) versus SU S338 (1.5 inch). The axle bore is not compatible. Installing SU S339 on an SU S338-equipped truck will cause excessive wheel play and the wheel will slide off the axle under load.

Q: What brand wheels are equivalent to SU S339?

A: SU S339 is equivalent to Jungheinrich EL-18 and Toyota 7FBE18 load wheels. All three have the same 1.25 inch bore and 1800 lbs capacity. Cross-brand replacement is possible if the bolt pattern matches your axle assembly.

Q: How do I know if SU S339 wheels are failing?

A: Warning signs include visible cracking in the rubber tread, a grinding or squeaking noise when the truck moves, and excessive heat around the wheel hub after operation. If you see any of these symptoms, remove the truck from service immediately and replace both wheels on the axle to maintain balance.

Q: What is the bolt torque for SU S339 wheel installation?

A: SU S339 hub bolts must be torqued to 45 ft-lbs in a star pattern. This is lower than SU S338 (65 ft-lbs) because the hub diameter is smaller and threads are 7/16 inch versus 1/2 inch on the larger wheel. Over-torquing will strip the bolt threads.

Q: How often should SU S339 wheels be greased?

A: If your wheel has an open bearing design (not sealed), grease the wheel bearing every 3-4 months or after 200 operating hours, whichever comes first. Use lithium-based grease rated for wheel bearings. Over-greasing will overheat the bearing and cause premature failure.