Product Description

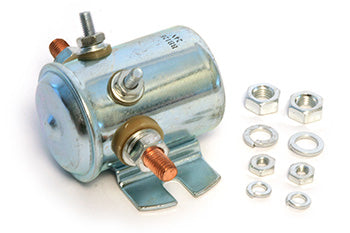

12VDC intermittent-duty solenoid with three stud terminals for electric lift truck applications, compatible with part numbers SMR6007, 778021, and 979774. Utilizes copper alloy contacts and corrosion-resistant steel enclosure for high cycle reliability. Designed for standard mounting configurations.

Specifications

Electrical

| Coil Voltage | 12VDC nominal |

| Maximum Continuous Current | 150A (referenced comparable solenoid design) |

Part Numbers

| Manufacturer Part Number | 15-150 |

| Cross-Reference Part Numbers | SMR6007, 778021, 979774 |

| Equivalent Part Number | Solenoid Switch 15-150 |

Frequently Asked Questions

Q: What are the voltage and terminal specifications for the 15-150?

A: The 15-150 is a 12VDC intermittent-duty solenoid with three stud terminals. It is rated for 150A maximum continuous current and features a 3-post configuration suitable for standard electric lift truck switching applications.

Q: Which part numbers does the 15-150 cross-reference?

A: The 15-150 is cross-compatible with SMR6007, 778021, and 979774. Verify the three-stud terminal layout and mounting orientation match your equipment before ordering, as some cross-reference parts may have different mounting brackets.

Q: What materials does the 15-150 use for durability?

A: The 15-150 uses copper alloy contacts for reliable electrical switching and a corrosion-resistant steel enclosure to protect against warehouse moisture, salt air, and thermal cycling. These materials are selected to withstand high-cycle industrial duty.

Q: What types of lift trucks use the 15-150 solenoid?

A: The 15-150 is designed for electric lift trucks, pallet jacks, and material-handling equipment using 12VDC battery systems. The three-stud configuration is standard for hydraulic valve control and motor contactor switching on mid-duty industrial trucks.

Q: How does the 15-150 perform in wet or outdoor environments?

A: The corrosion-resistant steel enclosure provides protection against moisture exposure, but the solenoid is rated for indoor use or covered outdoor areas. Direct immersion or continuous spray conditions will degrade copper contacts faster; inspect terminals regularly in damp environments.

Q: What is the expected service life of the 15-150?

A: The 15-150 typically provides 3-5 years of reliable intermittent-duty service. Contact wear and copper oxidation reduce lifespan in high-cycle applications. Monitor for intermittent engagement failures or resistance changes. Replace if coil insulation tests indicate breakdown or if studs show severe pitting.